WillTech is a preferred supplier of ball sealing-plugs and screw-in orifices

See more

ScanWill’s compact hydraulic pressure intensifiers, offered in cast iron and steel, with a chrome finish, as well as in stainless steel for the oil & gas sector, transform low pressure supplied to the inlet port (15-200 bar/218-2,900 psi) to a higher pressure at the outlet port (from 20-4,000 bar/290-58,000 psi).

This allows you to achieve stronger cutting, improved clamping, or enforced breaking, to name but a few, without making large investments into new equipment or drastic changes to the configuration and footprint of your machinery. See key features and scroll through our model versions below, and view our full product range here.

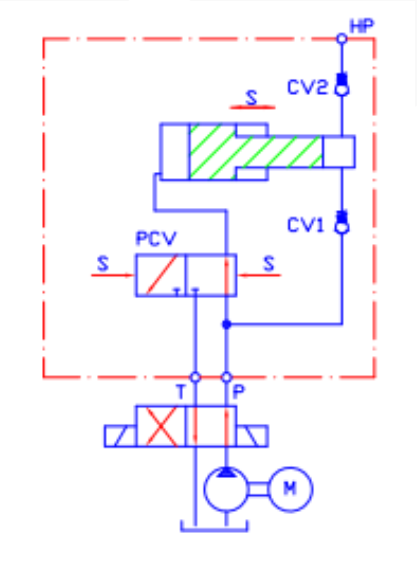

Standard version with no internal relief function. Requires the addition of an external tank line.

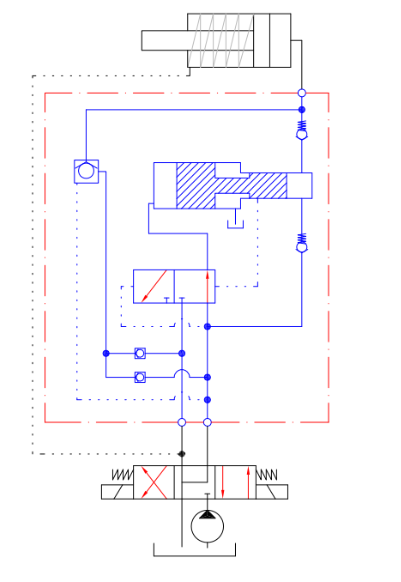

When applying flow to the P-port and connecting the T-port to tank, the full pump flow will go straight through the intensifier check valves CV1, and CV2 to the cylinder, allowing the rod to move out at pump speed. When the cylinder is filled up and the pressure has risen to pump pressure, the intensifier pistons automatically increase the pressure to the set end pressure. Keeping the pump connected ensures the intensifier will automatically work to maintain the end pressure in the cylinder in case the pressure drops. To relief the pressure an external solution will have to be made.

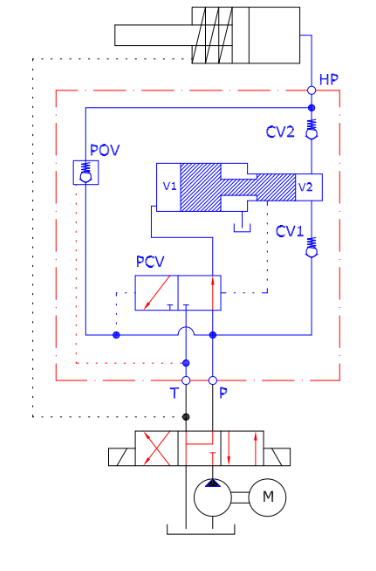

This version is equipped with the POV valve which functions as an internal relief function.

When applying flow to the P-port and connecting the T-port to tank, the full pump flow will go straight through the intensifier check valves CV1, CV2 and POV (optional) to the cylinder, allowing the rod to move out at pump speed. When the cylinder is filled up and the pressure has risen to pump pressure, the intensifier pistons automatically increase the pressure to the set end pressure. Keeping the pump connected ensures the intensifier will automatically work to maintain the end pressure in the cylinder in case the pressure drops. The integrated pilot operated check valve POV is activated by changing position on the directional valve positioned before the intensifier. By connecting the T- port to the pump and the P-port t tank, a pilot signal will open the POV, and a free passage from the high pressure side back to tank is created. This will decrease the pressure on the end pressure side and allow a cylinder piston to retract. The oil from the cylinder is lead out the intensifier via the B port through the directional valve.

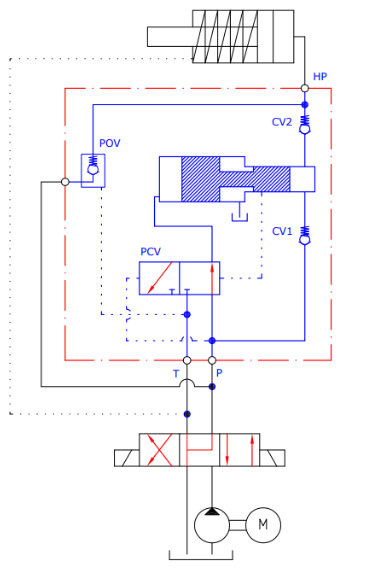

The XP version ensures that the oil is being returned to tank after each high pressure cycle. This helps keeping the temperature low and the filtration high. The XP connecting is made as an external line. It is best used for high dynamic high pressure applications.

When applying flow to the P-port and connecting the T-port to tank, the full pump flow will go straight through the intensifier check valves CV1, CV2 and POV (optional) to the cylinder, allowing the rod to move out at pump speed. When the cylinder is filled up and the pressure has risen to pump pressure, the intensifier pistons automatically increase the pressure to the set end pressure. Keeping the pump connected ensures the intensifier will automatically work to maintain the end pressure in the cylinder in case the pressure drops. The integrated pilot operated check valve POV is activated by changing position on the directional valve positioned before the intensifier. By connecting the T-port to the pump and the P-port t tank, a pilot signal will open the POV, and a free passage from the high pressure side back to tank is created. This will decrease the pressure on the end pressure side and allow a cylinder piston to retract. The oil from the cylinder is lead out the intensifier on the side port POV, ensuring filtered and cooled oil for the next cycle.

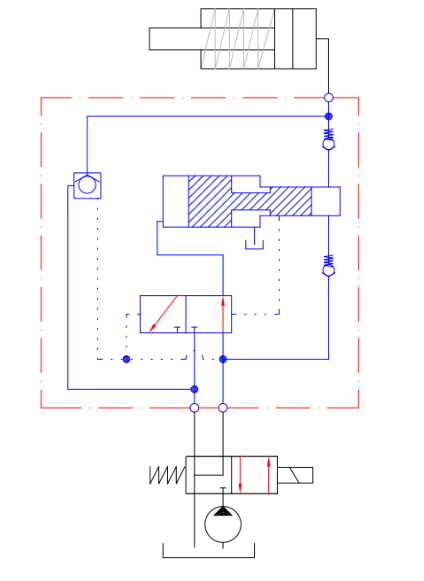

The AV version automatically releases the pressure when the directional valve is changed to neutral. This could be an advantage for safety issues since the pressure will release if the power is cut.

When applying flow to the A-inlet-port and connecting the B-inlet-port to tank, the full pump flow will go straight through the intensifier check valves CV1 and CV2 through A-outlet to the cylinder, allowing the rod to move out at pump speed. When the cylinder is filled up and the pressure has risen to pump pressure, the intensifier pistons automatically increase the pressure to the set end pressure. Keeping the pump connected ensures the intensifier will automatically work to maintain the end pressure in the cylinder, in case the pressure drops.

During pressure build up the AV check valve is closed. When pump pressure is removed the AV check valve will automatically open, and a passage from the cylinder through the A-outlet back to tank is opened.

The AVD version is equivalent to the AV, but is designed to handle a 4/3 directional valve.

When applying flow to the A-inlet-port and connecting the B-inlet-port to tank, the full pump flow will go straight through the intensifier check valves CV1 and CV2 through A-outlet to the cylinder, allowing the rod to move out at pump speed. When the cylinder is filled up and the pressure has risen to pump pressure, the intensifier pistons automatically increase the pressure to the set end pressure. Keeping the pump connected ensures the intensifier will automatically work to maintain the end pressure in the cylinder, in case the pressure drops. During pressure build up the AVD check valve is closed. When pump pressure is removed the AVD check valve will automatically open, and a passage from the cylinder through the A-outlet back to tank is opened. The AVD is designed to function with single and double acting cylinders.

Click to download the latest product brochure, and learn all about the wide range of ScanWill pressure intensifiers and tool solutions.

Sign up for the ScanWill newsletter

See more