WillTech is a preferred supplier of ball sealing-plugs and screw-in orifices

See more

WillTech, a business unit of ScanWill, offers a range of Ball Sealing Plugs manufactured in the USA, as well as a range of Screw-In Threaded Orifices.

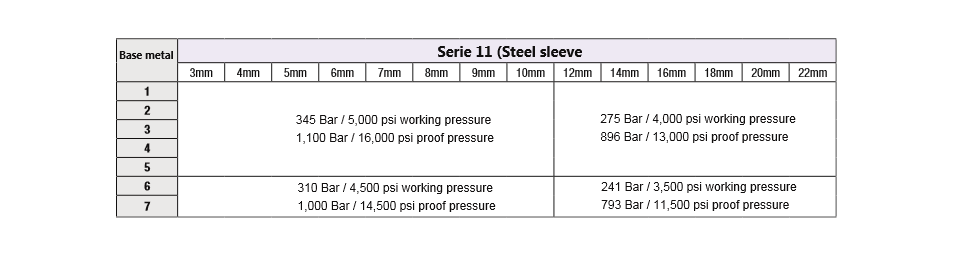

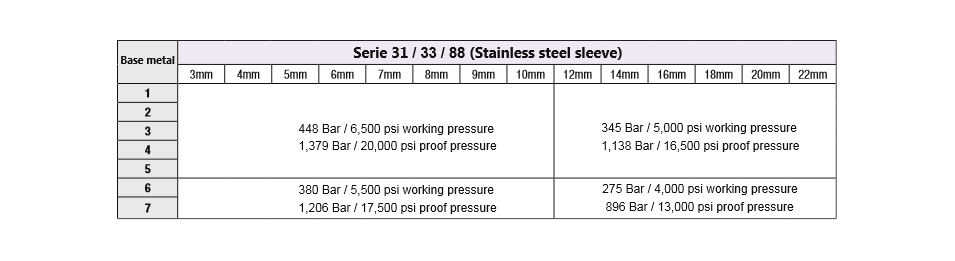

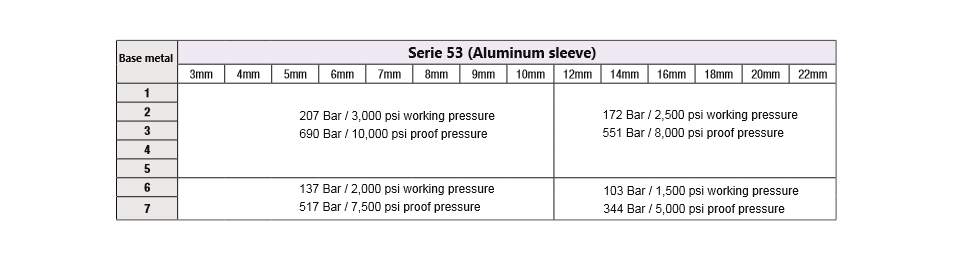

The ball sealing-plugs consist of an expanding metal sleeve and a steel ball. The sleeve is designed with several sealing rings, which cut into the bore to be sealed as the ball is driven into the sleeve. The ball sealing-plugs are offered in the materials steel, stainless steel, and aluminium.

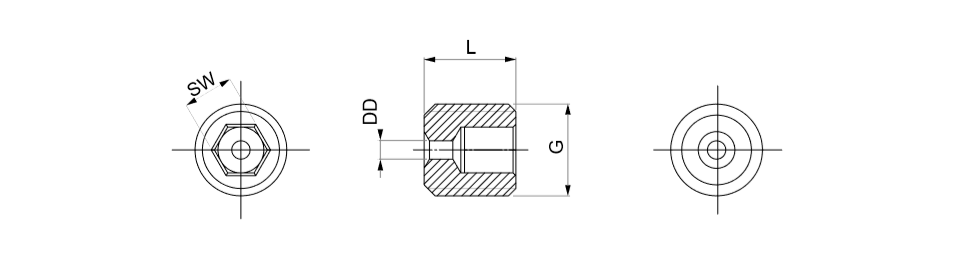

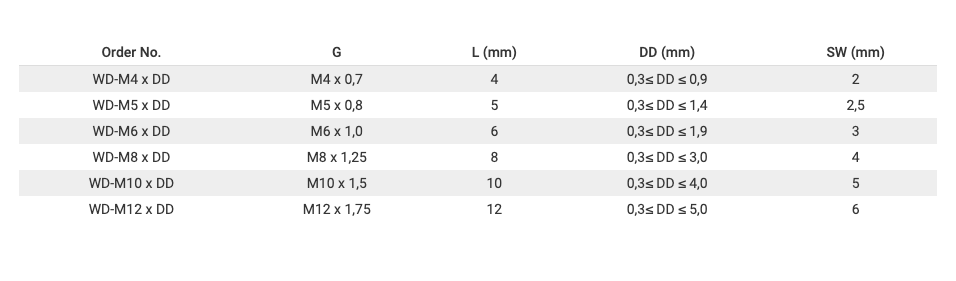

The screw-in orifices are offered with several metric threads and with orifice diameters from 0,3 mm to 5,0 mm. The screw-in orifices are made from stainless steel.

For quick, easy, and reliable sealing of cross bores.

The easy, fast, and cost-efficient way to control the flow.

WillTech Ball Sealing Plugs are the perfect solution for sealing off cross bores quickly, easily, and reliably.

Features

Application examples

Materials

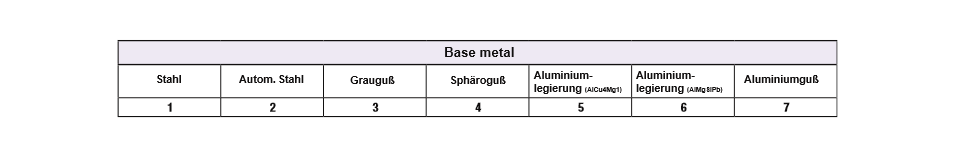

The ball sealing plugs are offered in 5 different materials:

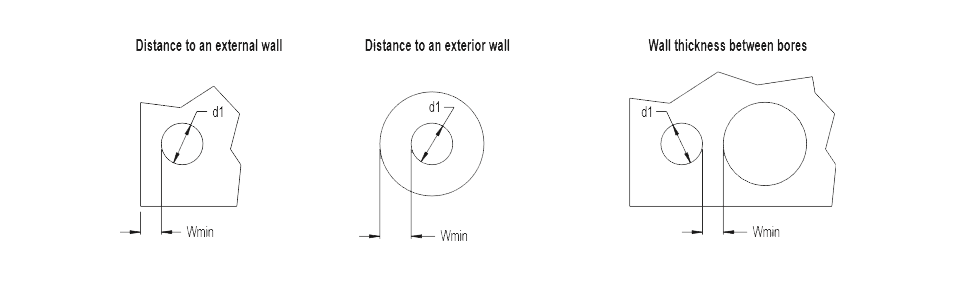

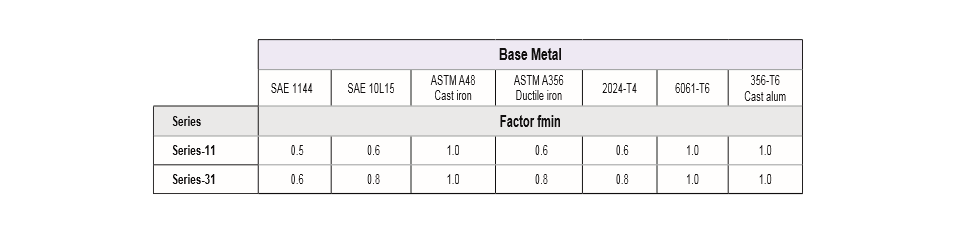

Minimum wall thickness and distance from an edge

The radial expansion of the Sealing Plug causes the housing material around the plug to deform plastically. A proper minimum wall thickness, or distance from an edge is necessary to optimize the strength of the mechanical connection. The operating hydraulic pressure, thermal cycling, plug type and characteristics of the base metal must all be considered when determining these values. Please contact us for additional information.

The guidelines for a minimum wall thickness or distance from an edge (Wmin) are expressed below. These minimum values produce only slight deformation on the exterior profile of less than 20µm. This does not affect the performance of the Sealing Plug. Using Wmin values less than those recommended can cause overloading of the base material. This can adversely influence the function of the Sealing Plug. Please contact us for additional information.

Wmin Guideline Values

Sealing Plug Diameter:

· d1 ≥ 4mm: Wmin = fmin * d1

· d1 < 4mm: Wmin = fmin * d1 + 0.5mm

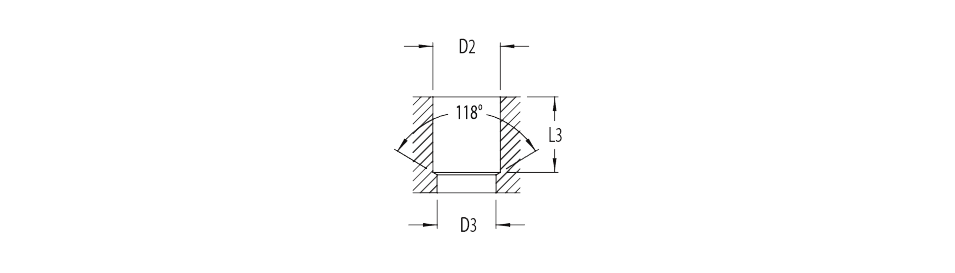

Preparation of the bore to be sealed

The dimensions of the bore to be sealed are shown on the product information sheet for the selected ball sealing plug. The diameter D2 for the for the sealing plug and the diameter D3 for the bore to be sealed are shown with tolerances, which must be kept.

The roundness of the bore D2 for the ball sealing plug must be within 0,05 mm.

The surface finish of the bore D2 must be within Rz 10-30 µm, which is especially important for hard materials. We recommend making the bore D2 with a drill, and to completely avoid a reamer.

In the section Design Guidelines parameters for the position and the recommended wall thicknesses are given.

It is important to avoid any longitude scratchec in the bore D2, as these may result in leakage. The bore must be cleaned, and free from chips, oil etc.

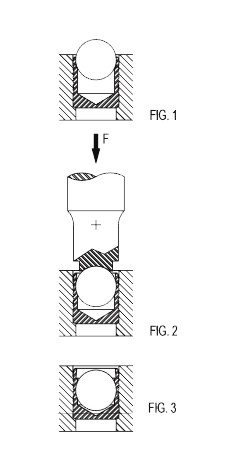

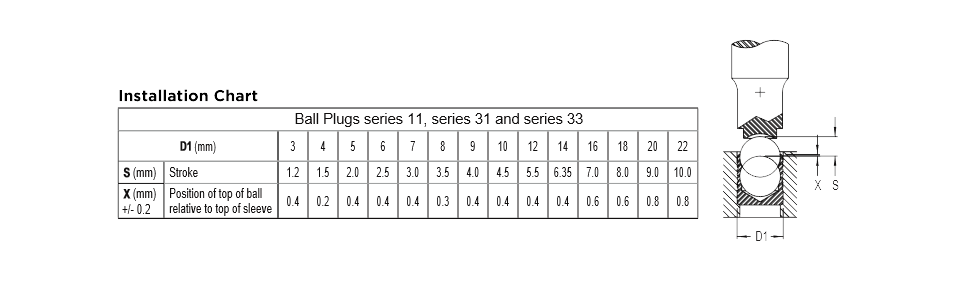

Installation instructions for the Sealing Plugs Series 11, 31 and 33.

Bore Preparation

Ensure the bore is clean and nor chips, grease or oil is present. Installation Procedure

Installation Procedure

– Insert the plug into the counterbored hole with the ball facing out, seated against the counterbore shoulder.

– It is important that the correct drill and counterbore size are selected so that the plug is properly supported during installation and a good seal is obtained.

– Press the ball into the sleeve so that the top of the ball is slightly below the top of the sleeve (see FIG. 2 and 3). Approximate values for S (stroke) and X are listed in the table below.

– Be sure to purchase the correct installation tool for each plug size selected.

– The ball plugs can be installed using a hammer and the correct hand installation tool. An arbor or an air hammer with the correct air hammer installation tool can also be used.

– The installation of the ball plugs can also be automated. Feel free to contact us to assist you with your application. Our technical staff would be pleased to help you design and build a custom semi or fully automated installation system.

The values offered are to be used as a guideline. The base metal chosen for your specific application, the surface treatment, hole size and surface finish all affect seal performance. Please contact us for additional information.

WillTech threaded orifices provide an easy, fast and cost-efficient way to control the flow.

The orifices are extremely easy to use, come in a compact design made from stainless steel W 1.4305, available with M4, M5, M6 and M8 thread. WillTech offers orifices from D0,3 mm to D5,0 mm.

Contact us with any questions or inquiries, and together, we’ll find a solution from WillTech’s wide range of ball sealing plugs and screw-in orifices.

Nicklas Hemmingsen, Global Sales Manager

These guidelines describe how WillTech and Scanwill Fluid Power ApS processes your personal information when you visit our website. By “personal information”, we mean any information about an identified or identifiable natural person. We focus on protecting all our customers´ privacy, and processing personal information in accordance with current laws, including the Personal Data Demand (GDPR).

This privacy policy provides an overview of the information collected and how the information is processed.

The CEO is responsible for Scanwill fluid Power ApS´ processing of personal data at scanwill.com, Scanwill.de, and Scanwill.dk. It is optional for those who visit websites to provide personal information in connection with services such as filling out an order form, sending an e-mail with a request or calling us. By filling in an order form, sending us an email or calling us, you agree that Scanwill Fluid Power ApS uses your personal data (name, email address, company name, and phone number) to provide you with relevant messages and offers.

Cookies

A cookie is a small text file, that the website you are visiting asks to save on your computer. Cookies are used on many websites to give visitors access to various functions. It is possible to use the information in the cookie to follow a user´s surfing activities. There are two types of cookies: cookies and session cookies. Cookies save a file on your computer for a prolonged period. They are used for example, for functions that indicate what is new since you last visited the web site concerned. Session cookies are used while you are surfing on a website and are temporarily stored in your computer´s memory, for example to keep track of what language you have chosen. They disappear when you close your browser.

Scanwill Fluid Power ApS uses the following cookies: One session cookie that identifies the session between client and server, and one cookie that collect statistics about how visitors navigate the website (Google analytics). If you wish to disable cookies, you should do so in the settings for your browser.

Use and exchange of personal data

Scanwill Fluid Power ApS does not use, disclose or exchange personal information about visitors to the websites in any way other than described above. Your information will not be disclosed to other organizations, individuals or businesses.

Insight

You are entitled at any given time to gain insight into the personal information we are processing about you, and the right to request correction or deletion of the information collected. You have the right to withdraw your consent. If you have requests or questions, please send us an email on info@scanwill.com.

Sign up for the ScanWill newsletter

See more